How to Choose the Right Bucket for Your Wheel Loader

Choosing the right wheel loader bucket can help you complete projects efficiently, reduce equipment wear and tear, prevent repair needs and increase your machine’s life span. A quality bucket can help your team complete tasks such as grading, racking, loading and sorting to save significant time and create a safer worksite.

Understanding which types of buckets are available and how they differ can help you select the best option for each job. Modern wheel loader buckets have unique designs to handle specific materials, allowing you to optimize your equipment for each project’s needs and site conditions.

Types of Wheel Loader Buckets

Manufacturers design specialized wheel loader buckets to handle various materials such as coal and fertilizer. Investing in a single bucket or having a variety of bucket options on hand can increase your company’s capabilities.

Consider the following types of buckets you can add to your construction fleet.

General-Duty Bucket

A general-duty bucket is an excellent option for any fleet because of its versatility. This bucket is engineered for maximum filling and material retention, and it features a curved edge for landscaping, stockpiling, rehandling and general tasks.

Rock Buckets

Rock buckets are durable enough to withstand harsh and abrasive environments, making them the ideal option if you need to move or work with heavy debris, concrete or rocks. A rock bucket is perfect for working in quarries and performing mining operations because it can endure tough conditions.

Light Material Buckets

A light material bucket is perfect for low-density materials due to its large capacity. Light buckets can accommodate various materials, but you must ensure loads are loosely packed so they are not too heavy. You can use them for the following materials:

- Mulch

- Peat moss

- Snow

- Wood chips

- Coal

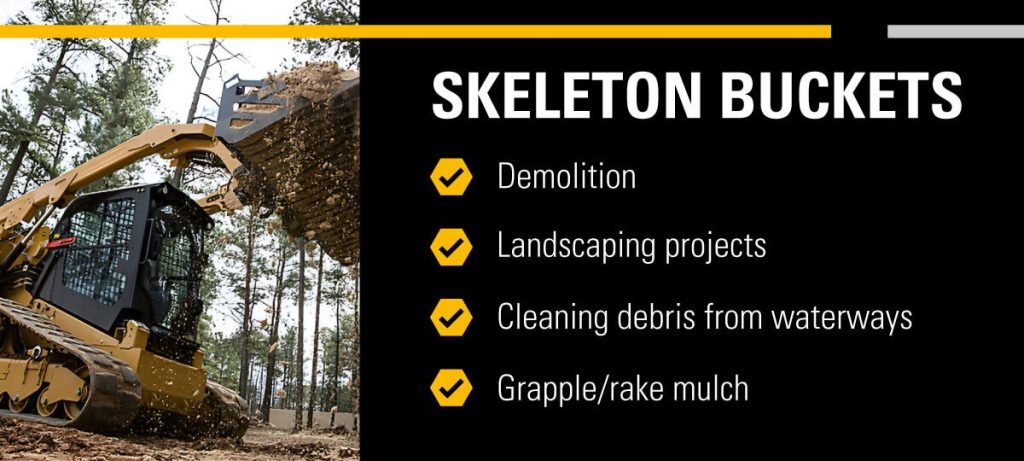

Skeleton Buckets

The skeleton bucket is characterized by its ribbed, gap-filled design, which is ideal for sorting and sifting. The gaps allow this bucket option to separate finer particles from larger chunks. With a skeleton bucket, you can easily pick up heavier debris such as large rocks and leave surrounding soil or water behind.

Multipurpose Bucket

A multipurpose bucket has a clam-shell shape that helps it grip and pinch materials. The teeth-like edges function efficiently for tasks such as digging, material handling, back-filling, excavating and high-dumping. The multipurpose bucket is one of the most common bucket designs and a must for any construction site.

Tips for Choosing a Wheel Loader Bucket Attachment

There are a couple factors to consider when choosing a wheel loader bucket attachment. Answer the following questions to make the best decision.

What Material Do I Need to Move?

Different materials demand different bucket types. For example, sites containing heavy materials may need a heavy-duty rock bucket, while those with mixed materials may require a general-duty bucket. The weather conditions will also affect the material you’re moving. For instance, if a job site is sandy, rain will cause the sand to weigh more than usual, resulting in the need for a heavy-duty bucket option.

What Size Should I Get?

Choosing the right size bucket for your project is important. Using a bucket that is too small can slow down operations if you need to move heavy materials. At the same time, using a bucket that is too large can overtax your wheel loader depending on its size. Selecting a slightly larger bucket is typically better than using one that’s too small, but it’s important to avoid overloading the machine and maintain worker safety.

Consider factors such as safety, loading capacity and the containers you load on your machine when evaluating which size bucket to use. Each wheel loader has a loading capacity indicating how much weight it can carry in attachments and the materials it handles. Check your equipment’s user manual before attaching a bucket to ensure the machine can handle it safely.

What Design Do I Need?

The right bucket design is critical to work efficiently and extend your bucket’s life span. Consider what type of edge you will need for your material. For example, a clean, simple edge works for softer materials, while teeth help you pick up rougher debris.

The durability of the bucket’s edge is also important. A bucket edge made of softer metal often cannot handle abrasive materials, but reinforced steel is an excellent option for heavy-duty debris.

Features of high-quality wheel loader buckets include:

- Additional guarding and wear protectors

- Durable teeth, side cutters and edges

- Long bucket floors

- Curved side plates

- Add-ons such as cutting edges and bolt-on teeth

Important Safety Considerations

It’s crucial to select the right wheel loader bucket design and size to ensure safety. Using the right bucket for each job and machine prevents your wheel loaders tipping over or dropping material. Remember to keep the bucket low when transporting materials or making turns. Always follow safety guidelines when operating, inspecting or repairing a bucket, and never overload your machine with a bucket that’s too heavy.

Why Consider Used Wheel Loader Buckets?

Buying used wheel loader buckets saves both money and time. Depending on your budget, the cost savings of purchasing a used bucket may allow you to invest in more buckets and grow your fleet of equipment and attachments.

If your current bucket is damaged and you’re looking for a quick replacement, buying used gives you that option since there’s no need to wait. Buying through your local Cat® dealer will also mean less shipping costs and reduced delivery time.